Introduction

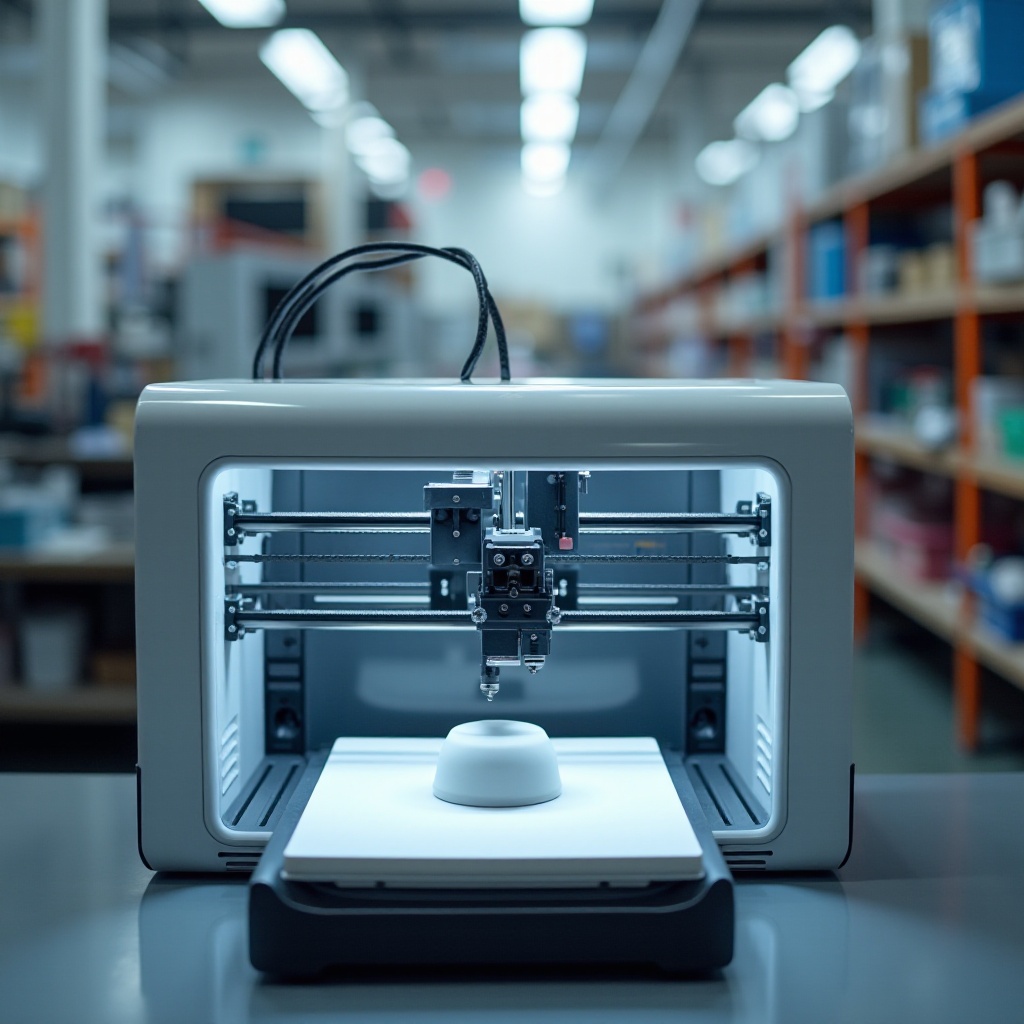

3D printing has revolutionized manufacturing and creativity by transforming digital designs into tangible objects. This diverse technology allows the production of various items, ranging from everyday household items to intricate medical devices. With its ever-growing capabilities, 3D printing is becoming a vital tool in various industries. In this article, we will explore the fascinating range of products that can be created with 3D printers, uncovering the technology’s impressive versatility.

Consumer Products and Household Items

3D printing’s ability to create customized, intricate designs has made it a popular choice for producing consumer products and household items.

- Home Décor: Items like vases, lampshades, and picture frames can be easily crafted, allowing for unique and personalized home décor.

- Kitchen Utensils: Kitchen gadgets, including measuring cups, cookie cutters, and spice racks, can be tailored to fit specific needs and styles.

- Toys and Games: Custom toys, board game pieces, and puzzles are printable, providing fun and creativity for all ages.

- Repair Parts: Replacement parts for household items, such as knobs and clips, can be created to extend the life of everyday objects.

The accessibility of 3D printing for consumers amplifies the convenience and personalization available in household management. These practical uses showcase the transformative potential of 3D printing in daily life.

Medical and Healthcare Applications

Medical and healthcare sectors have embraced 3D printing for its precision and adaptability. This technology significantly impacts the creation of patient-specific solutions.

- Prosthetics and Orthotics: Custom prosthetic limbs and orthotic devices can be tailored to each patient, improving comfort and functionality.

- Surgical Tools: Surgeons can use 3D-printed models of patients’ organs to plan complex procedures, enhancing the accuracy and outcome of surgeries.

- Dental Implants: Precise dental implants and braces can be printed, ensuring a perfect fit and faster production times.

- Bioprinting: Although still in experimental stages, 3D bioprinting holds the promise of creating tissues and even organs for transplants, reducing the dependence on organ donors.

The medical applications of 3D printing show remarkable potential in improving patient care and efficiency within healthcare systems. This innovation bridges the gap between conventional methods and customized healthcare solutions.

Industrial and Engineering Uses

3D printing has also made substantial inroads in industrial and engineering domains. Its ability to produce complex parts quickly and accurately offers significant advantages.

- Prototyping: Engineers can create and test prototypes faster, iterating designs as needed without incurring substantial costs.

- Tooling and Jigs: Custom tools, jigs, and fixtures can be printed to assist in the manufacturing process, improving efficiency and reducing downtime.

- Automotive and Aerospace Parts: Critical components in cars and planes, such as brackets, housings, and even whole assemblies, can be produced to meet exact specifications and reduce weight.

- Construction: 3D printing in construction uses concrete or alternative materials to build housing units and commercial buildings, reducing waste and labor costs.

Industrial applications of 3D printing demonstrate its capacity to streamline manufacturing processes, enhance innovation, and reduce production times. The versatility in material and design underscores its transformative impact on engineering and industrial practices.

Creative and Artistic Endeavors

Artists and designers have adopted 3D printing for its boundless creative potential. This tool allows for unprecedented freedom in artistic expression and product design, bridging the artistic and technical fields.

- Sculptures and Artwork: Artists can bring their digital designs to life, creating intricate sculptures and installations that were previously impossible.

- Fashion Design: Custom jewelry, accessories, and even clothing can be 3D-printed, pushing the boundaries of traditional fashion production.

The creative applications of 3D printing enable new forms of art and expression, making it an invaluable tool for artists and designers seeking innovation.

Educational Applications

Educational sectors benefit from incorporating 3D printing into curricula, helping students grasp complex concepts through hands-on learning.

- Learning Aids: Models of molecules, architectural structures, and historical artifacts can be printed for interactive learning.

- STEM Projects: Students can design and print their projects, fostering creativity, problem-solving, and technical skills.

The use of 3D printing in education provides dynamic and engaging learning experiences, encouraging students to think critically and innovate.

Future Possibilities and Innovations

The future of 3D printing holds incredible promise. As technology advances, new materials and methods will further expand its capabilities.

- Space Exploration: 3D printing can create tools and parts needed for long-term space missions, potentially enabling the construction of habitats on other planets.

- Sustainable Solutions: Using biodegradable and recycled materials in 3D printing can reduce waste and support sustainability efforts.

- Food Production: The prospect of printing food items, customized in shape and nutritional content, could revolutionize how we prepare and consume food.

These future innovations highlight the vast potential of 3D printing, underlining its capacity to drive sustainable and transformative technological progress.

Conclusion

3D printing has emerged as a versatile and transformative technology, influencing various facets of life. From everyday household items to groundbreaking medical solutions, the range of applications is vast and continually evolving. As advancements continue, the potential of 3D printing promises to unlock even more possibilities, making it a prime driver of innovation across numerous industries.

Frequently Asked Questions

What materials can be used in 3D printing?

3D printing materials include plastics, resins, metals, ceramics, and even certain food ingredients. Advanced printers can also use composites and biocompatible materials for medical applications.

How long does it take to print a 3D object?

The printing time varies depending on the size, complexity, and material of the object. It can range from a few minutes to several days.

What are the limitations of 3D printing?

Current limitations include material restrictions, print size constraints, high initial setup costs, and the necessity for post-processing to achieve the desired finish. Future advancements aim to mitigate these challenges.